Characteristics and Paving and Installation Status of Marble Mosaic

March 17,2022

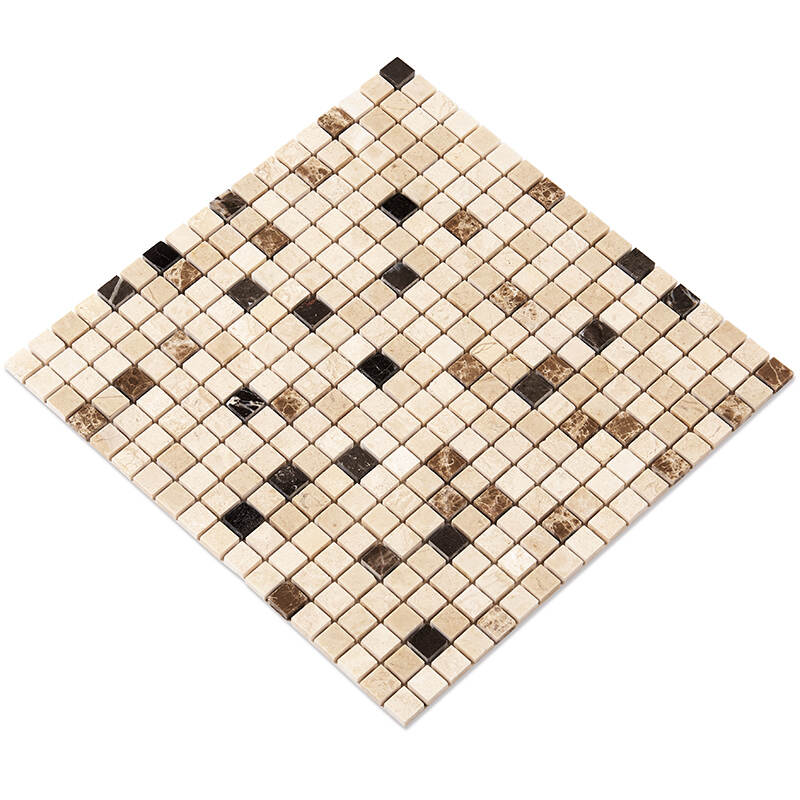

As far as the current requirements for decoration and material selection are concerned, the mosaic pattern with exquisite and delicate mosaic is generally selected as the base material of the mosaic, which is 1cm long and 0.5era thick.

However, the 1cm crema royal diamond polished marble mosaic has congenital defects

Firstly, there is a large difference in particle thickness due to stone cutting error, and the maximum difference in particle thickness of a board surface can reach 0.3cm;

Secondly, the gap is not clear, many particles are almost densely spliced, and even if there is a gap, it is of different sizes;

The third is that the cementation material used for the back net is oily adhesive. More than half of the mesh holes in the gap of the back net are closed by the back glue, and the cement mortar cannot be squeezed into the thassos herringbone polished marble mosaic gap from the back. All these have a direct impact on the decorative effect and the strength of components after installation.

Current situation of marble mosaic paving and installation

At present, the thassos herringbone polished marble mosaic paving method is similar to the traditional mosaic paving method. The difference is that the bonding effect of the bonding material between the back net and the base course is poor, the particles are not connected with the bottom slurry, and the paving construction has no function of strengthening the particle strength as a whole.

Specific paving procedures

First, remove the garbage from the base course and spray water to wet the mortar layer; The second step is to evenly scrape and level the prepared glue containing mortar on the base surface, then place the thassos herringbone polished marble mosaic of the whole plate, tap the component surface with an iron plate, and the pavement is completed.

After the cement material passes the curing period, the 2cm blue forest hexagon polished marble mosaic with regular gap shall be scraped and filled with sealant, but the small particles with LCM specification cannot be reinforced because of their fine gap, and the general slurry cleaning cannot be filled;

Even if a few gaps can be filled in batches, they will also cause gaps of different colors. Compared with the traditional paving effect, the construction method is the same, but the effect is very different.

Here, we need to pay attention to the congenital defects of the whole plate of small particle blue forest hexagon polished marble mosaic and the rigid application of the construction methods after the day after tomorrow, resulting in the lack of due strength and due decorative effect (referring to the standardized gap and uneven particles) after the component construction.

Reason

- First, the adhesive force between the back net and the base course is not strong, that is, the back net with the oily adhesive surface is bonded with the base course water-based adhesive, which is easy to cause hollowing of components;

- Second, the back mesh lattice is closed by back glue, the particles are only cemented with the back mesh and cannot be connected with the bottom slurry, the periphery cannot be filled and reinforced, and it is easy to thresh;

- Third, the gap is not standardized, and there is no decorative effect of granular profiles;

- Fourth, due to the inconsistent particle thickness, the crema royal diamond polished marble mosaic particles after installation are uneven and the decorative effect is poor. This shows that the current paving and installation construction has not developed new construction methods according to the characteristics of profiles, resulting in the lack of due strength and decorative effect of components.