All You Need To Know About Porcelain Mosaic

March 21,2022

Mosaic is a delicate decoration made of mosaic. It is also called brocade brick, which is divided into ceramic brocade brick and glass brocade brick. In this paper, we will introduce porcelain mosaic.

What Is Porcelain Mosaic?

Ceramic mosaic is inlaid handicraft and inlaid brick. It is also called "paper stone" because it is arranged and pasted on a certain size of paper to facilitate laying.

Characteristics Of Porcelain Mosaic

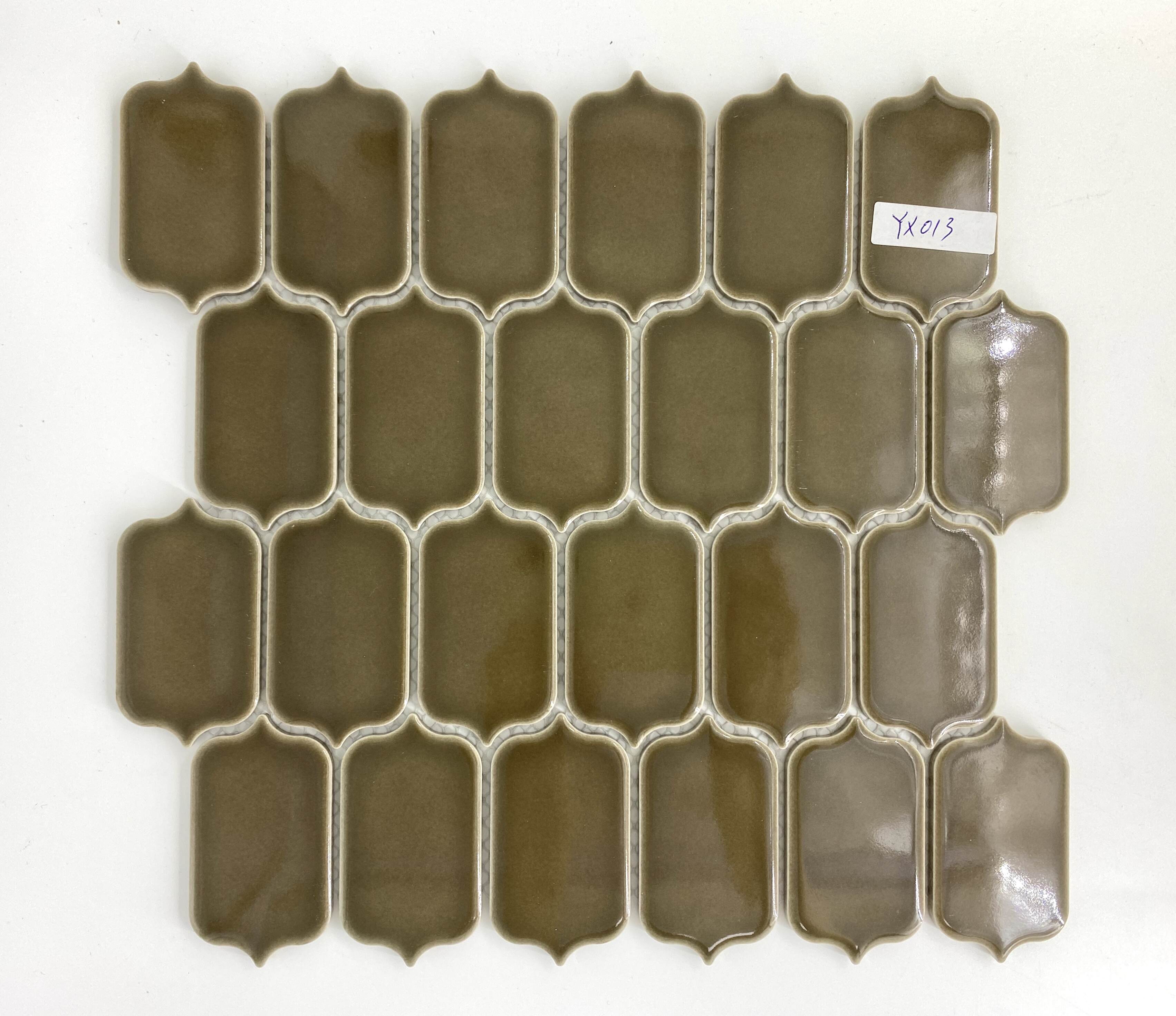

With the characteristics of waterproof, moisture-proof, wear-resistant and easy to clean, ceramic mosaic not only retains the simplicity and massiness of pottery, but also has the delicacy and luster of porcelain. The highlight lies in its profound cultural connotation. Now, there are various types of mosaic to meet people’ different demands, such as marrakesh white polished porcelain mosaic and canvas iris dust polished porcelain mosaic.

Common Specifications

The specification of a single block is generally 25 × 25mm、45 × 45mm、100 × 100mm、45 × 95mm, or a combination of small bricks in circular, hexagonal and other shapes. The specification of single connection is generally 285 × 285mm、300 × 300mm、318 × 318mm, etc.

Wide Applications

Ceramic mosaic is suitable for the decoration of fountains, swimming pools, bars, dance halls, gymnasiums and parks. Due to its excellent anti-skid performance, it is also commonly used in the floor decoration of family bathrooms, baths, balconies, restaurants and living rooms. Porcelain mosaic tile that looks like marble.

Construction Preparation Of Ceramic Mosaic

Materials

- Cement: 325 and above ordinary portland cement or slag Portland cement.

- Cement: 325 white cement (for joint wiping).

- Medium sand.

- Lime paste: when used, the lime paste shall not contain immature particles and impurities. (if lime powder is used, it shall be soaked in water one week in advance.

- Ceramic and glass brocade brick (mosaic): the variety, specification and color shall be in accordance with the design regulations, and the product certificate shall be provided.

Construction Condition

- The construction of ceiling and wall column plastering is completed.

- The concealed pipelines, electrical boxes and doors and windows on the wall and column surface have been installed and passed the inspection.

- The gap between the installed window sill plate, door and window frame and wall column shall be plugged and compacted with 1:2.5 cement mortar (the gap caulking material at the edge of aluminum doors and windows shall be determined by the design); Aluminum door and window cabinet shall be pasted with protective film.

- The wall column surface shall be clean (free of oil stain, laitance, residual ash, etc.), and the protruding wall column surface affecting the paving of brocade brick (mosaic) shall be chiseled and leveled. The excessively concave wall column surface shall be plastered and leveled with 1:2.5 cement mortar in layers. (water and wet before plastering).

Ceramic mosaic construction instructions

The wall or ground surface (bottom layer) must be cleaned and leveled without oil stain, looseness or sand. (if it is a swimming pool, it must be waterproof, and then the wall or ground surface (bottom layer) must be leveled.

Mix with special mosaic adhesive and water to form paste slurry (pay attention to drain water first and then powder).

- Use a toothed scraper to evenly apply the white paste paste on the wall, and scrape out stripe ripple or full scratch, with a thickness of about 3mm (the application area is about 1m2 each time, which should not be too large, so as not to be too late to pave and solidify the paste paste paste).

- The whole mosaic after unpacking shall be directly paved and pasted on the wall or ground, but please note that the mosaic of the puzzle shall be spliced in strict accordance with the spelling of the construction drawings. The paving requirements are as follows:

- After paving, the joint filling must be carried out after the mortar is completely treated (about 24 hours later). The requirements for joint filling are as follows:

(b).Apply the joint with a soft scraper, and clean the surface with a soft rag after about 10-20 minutes (it is strictly prohibited to use B. hard materials to clean the surface to avoid scratching).

In The End

The above are all the information about porcelain mosaic. If you are looking for beautiful mosaic, welcome to contact us.